| Product name | Okoume marine plywood |

| After sale service | Online technical support |

| Project solution capability | Total solution for projects |

| Design style | Modern or as your requirements |

| Place of origin | Shandong, China |

| Grade | First -class |

| Formaldehyde Emission Standards | E0 |

| Veneer Board Surface Finishing | Double-sided decoration |

| Face/back | F:Okoume or as your request |

| Core | C:Poplar, Eucalyptus, Birch, Combi, etc |

| Size | 1220x2440mm/1250x2550mm/as Request |

| Thickness | 4mm, 6mm, 9mm, 12mm.15mm, 18mm,21mm, 25mm.28mm etc |

| Glue | E0, E1, E2, MR, WP, Melamine |

| Density | 500-700kgs /M3 |

| Color | Solid color, wood grain, marble grain, cloth grain etc We have melamine paper atlas,We have thousands of different color styles. We can provide customized service to produce the same color according to customer's samples |

| Moisture | 8-14% |

| Water absorption | <10% |

| Certification | CE ,FSC ,CARB ,EPA |

| Application | Home decoration, panel furniture, cabinet wardrobe, bathroom cabinet and other fields. |

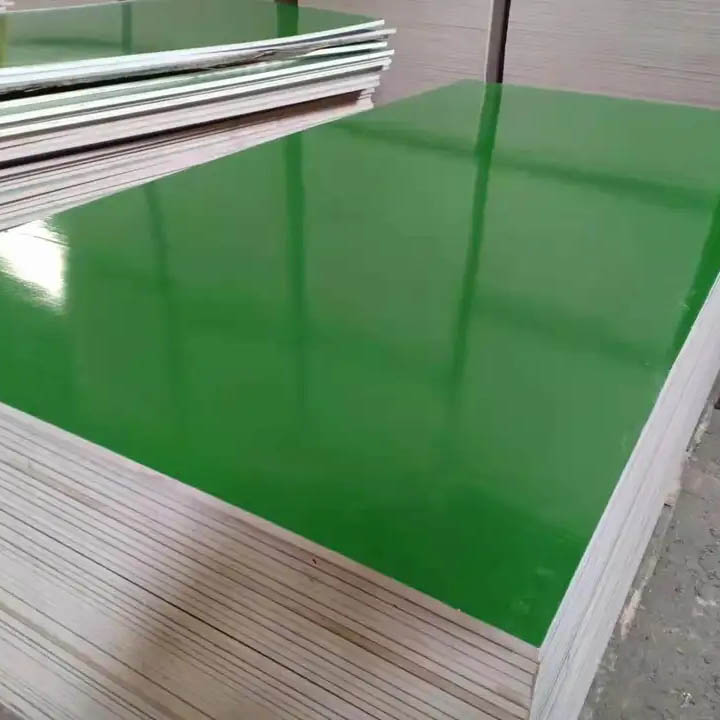

3mm Waterproof Laminated Okoume Marine Plywood sheet

Shop online for high-quality and reliable 3mm Waterproof Laminated Okoume Marine Plywood sheets. We are a factory, ensuring top-notch craftsmanship.

Request a QuotePRODUCTS DETAILS

Hot Products

Plastic film faced shutter formwork construction plywood

Black film faced plywood with logo

Commercial poplar furniture plywood

PINE Oriented Strand Board OSB3 Flakeboards

Fire retardant MDF /Fireproof MDF Board

Melamine Plywood for Furniture

Plain/raw chipboard /particle board

Brown film faced shutter formwork construction plywood

Factory wholesale OSB Waterproof oriented strand board 4x8 Panel for sheathing Roof materials

HPL Fireproof Board – Fire Rated Plywood

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours